Ibyiza bya CNC slant uburiri bwimashini ikoreshwa

Hamwe na digitale yimashini mugihugu cyacu hamwe niterambere ryiterambere ryihuse, byinshi kandi byinshi CNC

imisarani yinjizwa muriyi nganda kandi ikora ibikorwa byubukungu bwigihugu cyacu.CNC igitanda gito ni a

ugereranije neza na neza CNC umusarani, ntabwo ifite gusa ibisobanuro bihanitse, ariko kandi biraramba, ntabwo ifite a

isura nziza, ariko kandi ifite uburyo bwiza bushoboka.ibyiza.Kubwibyo, ubu bwoko bwibikoresho bikoreshwa cyane muri

imirima yindege, ibikoresho bya elegitoroniki, amasaha nisaha mugihugu cyacu, cyane cyane kubisobanutse neza, ibyiciro byinshi, kandi bigoye-

ibice.Tugomba gukoresha ubu bwoko bwibikoresho byimashini mugutunganya kugirango tumenye neza ko ibice byakozwe bikenewe

birashobora kugerwaho.Uru rupapuro rusesengura cyane cyane ibyiza bya mashini yo kuryama ya CNC ugereranije

igitanda gito CNC ibikoresho byimashini hamwe nigitanda cya CNC ibikoresho byimashini.

1. Intangiriro kumiterere yibanze ya lathe ya CNC hamwe nigitanda gito

1.1 Imiterere rusange yigitanda gito

Mubikorwa nyabyo byo gukata, uburiri bwa CNC umusarani ufite imikorere yigikoresho cyingufu zidasanzwe hamwe na sitasiyo ya sitasiyo ya sitasiyo 8, bityo irashobora kugira uruhare runini muri

gutunganya ibicuruzwa bitandukanye, cyane cyane mugutunganya ibicuruzwa bitandukanye, ibyiciro bito n'ibiciriritse Birakoreshwa muburyo bwo gutunganya

ibicuruzwa;cyane mubice bigoye kandi bisobanutse neza, biragaragara ko bifite ibyiza ibindi bicuruzwa bidafite.

1.2 Imyiteguro mbere yo gutangiza umusarani wa CNC hamwe nigitanda gito

Mbere yo gukoresha, uburiri bwa CNC umusarani ugomba kubanza gutsinda igenzura rya geometrike, hanyuma ugasukura imashini yose.By'umwihariko, ni ngombwa gukoresha

igitambaro c'ipamba cyangwa igitambaro kirimo imyenda yo gukora isuku.Imyenda y'ipamba cyangwa imyenda ya gauze ntigomba gukoreshwa muriki cyiciro kugirango wirinde imashini.Karaba

amavuta arwanya ingese cyangwa irangi rirwanya ingese ushyizwe hejuru yimashini, hanyuma usukure umukungugu hejuru yinyuma icyarimwe.Igihe kimwe, shyira i

amavuta yo gusiga yagenwe nuwabikoze kuri buri kantu kanyerera kandi hejuru yakazi.Mugihe kimwe, birakenewe kandi kugenzura neza niba byose

ibice byumusarani wa CNC hamwe nigitanda cyegeranye cyuzuyemo amavuta ukurikije ibisabwa bijyanye, kandi niba ibicurane biri mumasanduku akonje birahagije.

Niba amavuta muri sitasiyo ya hydraulic yigikoresho cyimashini hamwe nigikoresho cyo gusiga mucyumba cyikora gishobora kugera kumwanya wagenwe nurwego rwamavuta

icyerekezo.Mugihe kimwe, reba niba abahindura nibigize mumasanduku yo kugenzura amashanyarazi ari ibisanzwe, kandi niba plug-in ihuza umuzenguruko

imbaho zikora bisanzwe.Nyuma yimbaraga, dukeneye kandi gutangiza ibikoresho byo gusiga amavuta kugirango tumenye neza ko hari amavuta ahagije kuri

gusiga ibice no gusiga amavuta ya peteroli, kugirango ukore urukurikirane rwimyiteguro yimashini mbere yo kuyikoresha.

1.3 Gushiraho uburiri buto CNC umusarani

Uburiri bwa CNC umusarani ushyizwe ku rufatiro kandi bigomba kuringanizwa mu buntu kandi bigafungwa na ankeri.Nka ibikoresho bisanzwe byimashini

bireba, urwego rwo gusoma ntiruzaba ruri hejuru ya 0.04 / 1000mm, kandi niba ari igikoresho cyimashini za CNC zisobanutse neza, urwego ntiruzaba ruri hejuru

0.02 / 1000mm.Mugihe cyo gupima neza ibyashizweho, akenshi tugomba kubikora kubushyuhe buhoraho, kandi ibikoresho byo gupima bigomba gukoreshwa nyuma ya a

igihe cyo gushyiraho ubushyuhe.Mugihe ushyira umusarani wa CNC hamwe nigitanda cyegeranye, birakenewe kugabanya uburyo bwo kwishyiriraho uburyo bwo guhindura ibintu

byatewe nigikoresho cyimashini ya CNC bishoboka.Mugihe ushyira uburiri bwa CNC umusarani, ibice bimwe byigikoresho cyimashini ntibishobora gukurwaho bisanzwe.

Niba ibice bimwe bivanyweho, birashoboka ko bitera impagarara zimbere yumusarani wa CNC kugabanwa, bityo bikagira ingaruka kumyuma yimashini.

2.Gereranya uburiri bugoramye nigitanda kiringaniye ibikoresho bya mashini ya CNC

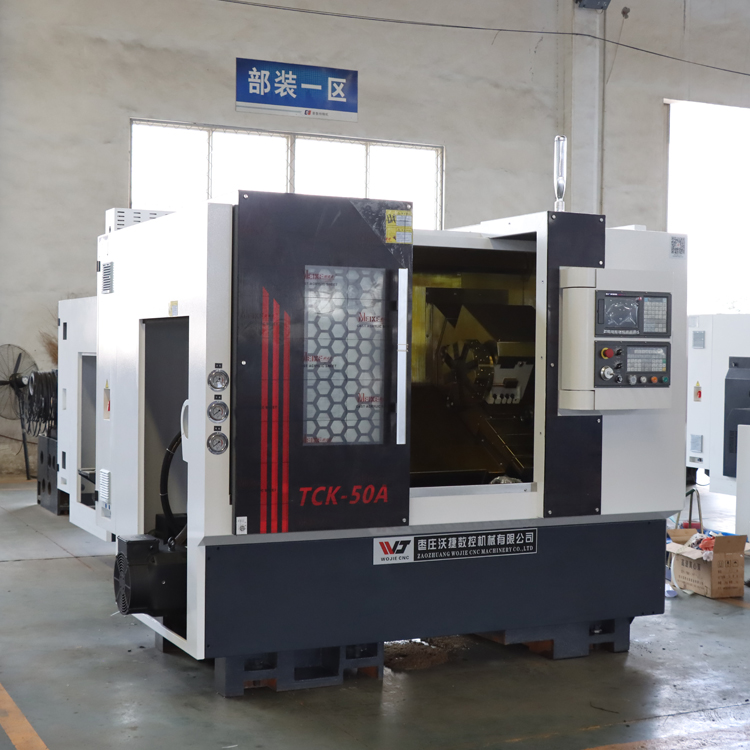

Mubushinwa, hari ubwoko bubiri bwibikoresho bya mashini ya CNC: uburiri buringaniye bwa CNC, bizwi kandi nk'imisarani ya CNC yubukungu, cyangwa ibikoresho byoroheje bya CNC, na

ikindi ni uburiri buto CNC umusarani, nanone bita umusarani uzwi cyane wa CNC hamwe numusarani wuzuye wa CNC.Dukurikije isesengura ryubwoko bubiri bwibikoresho bya mashini ya CNC,

ntabwo bigoye kubona ko umusarani wa CNC hamwe nigitanda cyoroheje ugereranije numusarani wa CNC hamwe nigitanda kiringaniye.Urebye kubikoresha, nubwo uburiri bwombi CNC

imisarani nigitanda gito CNC irashobora gukoreshwa muguhindura CNC, ibisobanuro byibice bishobora gutunganywa biratandukanye.Ibikoresho bya mashini ya CNC cyane

yagaragaye kugirango hamenyekane umusaruro rusange ugezweho, kandi ikintu kinini cyarwo ni automatike, igabanya imirimo myinshi isubirwamo.Uburiri bubi CNC

imisarani yose ikorwa nuburyo bworoshye bwa CNC bwo guhindura imisarani isanzwe, kuburyo akenshi bigoye kuyikora.Uburiri bwa CNC imisarani iratandukanye.Ni

byakozwe cyane cyane bishingiye kumahame shingiro yo gutunganya CNC kandi bifite aho bihurira.Kubireba, hari iterambere rigaragara.Izi nyungu

zitangwa mugihe cyo gushushanya kandi ntizishobora kuboneka binyuze mugutezimbere gukurikira.

2.1 Kugereranya ibikoresho byimashini kugereranya

Urebye imiterere yimisarani ibiri ya CNC, ikintu kinini kiranga umusarani wa CNC umusarani ni uko indege aho gari ya moshi ebyiri ziyobora iherereye ihwanye nindege yubutaka, mugihe uburiri bwa CNC umusarani uratandukanye, kandi indege aho imirongo ibiri iyobora iherereye irasa nindege yubutaka.Indege zirahuzagurika, kandi hazabaho kandi ahantu hahanamye, kandi inguni ihanamye irashobora kuba 30 °, 45 °, 60 °, 75 °, nibindi. Ukurikije imiterere yuburyo bwubwoko bwa kabiri bwibikoresho byimashini, dushobora kubibona uburiri bwigitanda kiringaniye CNC umusarani ni kare, naho uburiri bwigitanda cyegeranye CNC umusarani ni mpandeshatu iburyo.Duhereye kuri iyi ngingo, dushobora kubona ko mugihe cyubugari bumwe bwa gari ya moshi, ubwikorezi bwa X-icyerekezo cyigitanda cyegeranye kizaba kirekire kuruta icy'igitanda kiringaniye, bivuze ko imyanya myinshi yibikoresho ishobora gutegurwa.

2.2 Kugereranya gukata gukomera

Uhereye ku guca imikorere, agace kambukiranya umusarani wa CNC hamwe nigitanda cyegamye usanga ari kinini kuruta icy'igitanda kiringaniye kimwe

ibisobanuro, bivuze ko bifite imbaraga zo kunama no kurwanya torsion.Ibikoresho byo gukata umusarani wa CNC hamwe nigitanda cyegamye byaciwe kuva hejuru

y'akazi.Imbaraga zo gukata zirashobora kubikwa mucyerekezo kimwe nuburemere bwakazi, bityo spindle irashobora gukomeza kugenda neza.

kandi biragoye gutera guca guhindagurika.Umusarani uratandukanye.Imbaraga zo gukata zakozwe nigikoresho nigikorwa gikunze kubikwa perpendicular kuri

urupapuro rwakazi, rushobora gutera kunyeganyega.

2.3 Kugereranya gutunganya neza ibikoresho byimashini

Ku musarani wa CNC, imiyoboro yohereza ni umupira wohanze cyane, kandi hariho intera ntoya yohereza hagati ya screw nimbuto, ariko sibyo.

bivuze ko nta cyuho.Ariko, igihe cyose habaye icyuho, mugihe screw igenda mucyerekezo kimwe hanyuma ikagenda mucyerekezo gitandukanye, hazaba a

gusubira inyuma.Niba hari gusubira inyuma, byanze bikunze bizagira ingaruka kubisubiramo byukuri kandi amaherezo bigabanye neza.Imiterere ya

uburiri buhengamye CNC umusarani uratandukanye.Irashobora kugira ingaruka ku buryo butaziguye ku mupira w’umupira mu cyerekezo cya X, kandi uburemere buzagira ingaruka ku cyerekezo cya axial

ya screw, kugirango tumenye neza ko gusubira inyuma mugihe cyoherejwe ari zeru.Nyamara, X-icyerekezo cyerekezo yuburiri bwa CNC umusarani ntabwo bigira ingaruka kuri X-

imbaraga za axis, biragoye rero gukuraho icyuho.Ibi birahagije kwerekana ko umusarani wa CNC ufite uburiri buhengamye ufite ibyiza kurenza uburiri busanzwe

igikoresho cyimashini mubijyanye no gutunganya neza.

2.4 Kugereranya ubushobozi bwo gukuramo Chip

Urebye ingaruka za rukuruzi, biragoye ko umusarani wa CNC ufite uburiri buhengamye kubyara ibikoresho bizunguruka, kandi akenshi bifite inyungu runaka muri chip

gukuraho;ikorana kandi na screw yo hagati no kuyobora gari ya moshi kurinda ibyuma, kugirango wirinde ibyuma kuri screw no kuyobora gari ya moshi.kwirundanyiriza

phenomenon.Imisarani myinshi ya CNC ifite uburiri bugoramye izashiraho gukuramo chip.Igikorwa nyamukuru nuguhita ukuramo chip no kongera i

amasaha y'akazi.Nyamara, uburiri buringaniye bugarukira kumiterere, kandi akenshi biragoye kongeramo imashini ikuramo chip.

2.5 Kugereranya umusaruro wikora

Kubikoresho bya mashini ya CNC.Byaba ari ukongera umubare wibyuma cyangwa kugena ibyuma byikora byikora, intego nyamukuru nuguhindura umusaruro.Muri

ahazaza, hazabaho phenomenon umuntu umwe arinda ibikoresho byinshi byimashini kubikoresho byimashini za CNC.Umusarani wa CNC ufite uburiri buhengamye uzongeramo undi

gusya imbaraga umutwe, ibikoresho byo kugaburira byikora cyangwa manipulator, kandi mugihe kimwe, bizahita bipakira ibikoresho, birangize ibyubatswe byose

inzira yumurimo mugice kimwe, guhita umanura ibikoresho, hanyuma ugahita ukuramo chip, nukuvuga Byatejwe imbere muburyo bwuzuye

imashini yimashini ya CNC idakoreshwa ntamuntu ukeneye kuyobora.Kubwibyo, uburiri bubi CNC umusarani ntabwo ufite ibyiza byubaka niba ishaka kubimenya

kwikora.

2.6 Kugereranya ibiciro

Nubwo igitanda cyegeranye CNC umusarani uteye imbere kuruta uburiri bwa CNC umusarani muri byinshi, ntabwo byakiriye neza isoko.Uwiteka

Impamvu nyamukuru nuko uburiri bwa CNC ubwiherero bwa CNC akenshi budahenze, kandi umusaruro urihuta, kuburyo batoneshwa nitsinda ryinshi ryabaguzi rito-rito,

cyane inganda nto n'amahugurwa mato.Ugereranije, imisarani ya CNC ifite ibitanda byegeranye biragoye kuyikora, kandi uburiri nabwo

biremereye.X-axis nayo igomba kugira moteri ya servo ifite imikorere ya feri.Ingaruka nini nigiciro kinini cyo gukora.Kubwibyo

uko ibintu bimeze mubikorwa byinganda zigihugu cyanjye, inganda nyinshi zikeneye gusa gutunganya ibicuruzwa byo hasi, kandi ntibifite ibisabwa cyane

neza neza ibikoresho byimashini.Ibiciro byibanze cyane mugihe ugura ibikoresho byimashini.

3. Isesengura ryibyiza bya lathe ya CNC hamwe nigitanda cyegeranye mukoresha

Dukurikije isesengura ryavuzwe haruguru, twanzuye ko igikoresho cyimashini ya CNC yigitanda gifite ibyiza bikurikira, bikwiye kwitabwaho.

3.1 Irashobora gutunganya ibicuruzwa bihanitse

Kumashini yimodoka yibikoresho bya mashini ya CNC, mubusanzwe ni umupira wuzuye neza, kandi akenshi usanga hariho itandukaniro runaka hagati ya screw nimbuto, bityo

mugihe screw igenda mucyerekezo kimwe hanyuma ikagenda mucyerekezo gitandukanye, bizasubira inyuma kandi bizagira ingaruka kumashini yanyuma.CNC

ibikoresho bya mashini hamwe nigitanda cyegeranye bizahita bikora ku cyerekezo cyerekezo cyinkoni ya screw munsi yibikorwa bya rukuruzi, kandi akenshi biragoye kugira ikibazo mugihe

kwanduza.Kurugero, turashobora kubona ibinyomoro bisanzwe na screw, guhindura umugozi uhagaritse hejuru, hanyuma tukabisubiza muburyo bunyuranye.Tuzabibona

ibinyomoro bihora bikanda screw kuruhande rumwe, kugirango hatabaho gusubira inyuma.Niba turetse ibinyomoro Biragoye kubyara ingaruka nkiyi iyo ishyizwe neza

hamwe na screw.

3.2 Igikoresho cyimashini gifite ubukana bwiza, kandi ntabwo byoroshye gutera kunyeganyega mugihe cyo gutema.

Igikoresho cyimashini ya CNC hamwe nigitanda cyegamye akenshi iba iri hejuru yakazi iyo ikata.Imbaraga zo gukata zijyanye nuburemere bwakozwe na

Igikoresho cya spindle, bityo imikorere ya spindle izaba ihagaze neza, kandi guca vibrasiya biragoye kubaho.Ntabwo aribyo kumisarani isanzwe ya CNC

.Iyo barimo gukora, igikoresho cyo gukata hamwe nakazi kabyara imbaraga zo gukata hejuru, zitanga imbaraga zidahuye hamwe nakazi ka spindle,

biroroshye rero kubyara vibrasiya, gukora urusaku runini, kandi amaherezo bigira ingaruka kubikoresho byimashini.Gukomera no kuramba.

3.3 Ibindi byiza byuburiri bwa CNC ibikoresho byimashini

Dukurikije isesengura ryabanje, twasanze uburiri bwa CNC umusarani ukunda gukoreshwa cyane cyane muburyo butandukanye kandi buto-buto bwo hagati bwo gutunganya

ibice bitandukanye bisobanutse kandi bigoye kuzunguruka.Mugihe kimwe, turashobora kandi guhitamo hydraulic chuck na tailstock kugirango tugere kubintu byikora no gupakurura,

na sisitemu yatoranijwe hamwe nibikoresho bikora birashobora gufatirwa icyarimwe kugirango tumenye imikorere yo gusya no gusya.Irashobora kubona inyungu zimwe muri

gutunganya uruziga rw'imbere, uruziga rw'inyuma, intambwe, ubuso bwa cone, ubuso bwa serefike, groove, insinga zitandukanye hamwe n'ubuso bugoramye.Igihe kimwe, irashobora kandi

gutunganya amavuta atandukanye yubushyuhe bwo hejuru, amavuta ya titanium, amavuta arwanya ubushyuhe, ibyuma bitagira umwanda, Gutunganya ibintu bitandukanye byo guta no guhimba imyenda yicyuma, guta

ibyuma n'ibindi bikoresho.Kubakinnyi, kurakara bigomba gukorwa mbere kugirango bikureho imihangayiko.Inzira nyabagendwa ikoreshwa kuri X na Z-axis

inzira.Kuburyo bwose bwo gukata, gukosora kugororotse bigomba gukorwa kugirango harebwe niba ibikoresho byimashini bigenda neza kandi bikomeze gukata

Ukuri.Ubusobanuro bwibicuruzwa.

Ubwanyuma, uburiri bugoramye CNC lathe nayo ifite ubwizerwe bwiza, gukomera, kugororoka, kuramba, kwihuta gutunganya, kandi irashobora gukora ibintu bitoroshye, byiza kandi birangiye gutunganya

ku bikoresho bitandukanye bigoye-gutunganya.Umuzingi wa lathe ya CNC hamwe nigitanda cyegamye ufite gukurura no kugoreka, kandi umuvuduko ni mwinshi.Izi nyungu zose

bifasha cyane akazi kayo ko guca.

Igihe cyo kohereza: Mutarama-14-2023